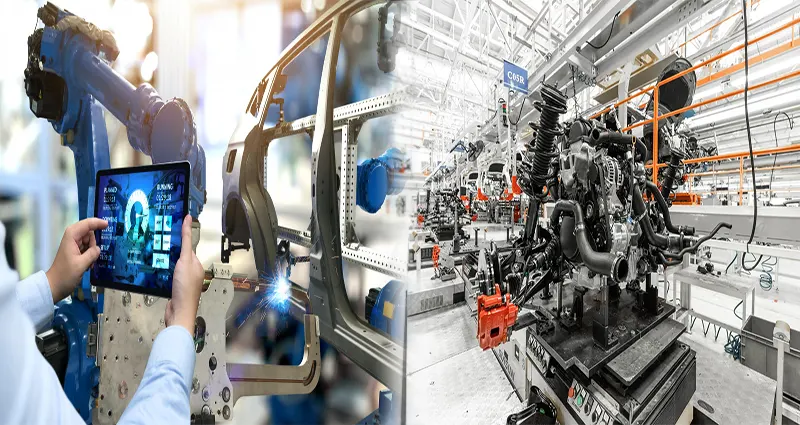

Artificial Intelligence (AI) is revolutionizing the automotive manufacturing industry, reshaping traditional processes, enhancing efficiency, and driving innovation to new heights. As automakers harness the power of AI technologies, the production line is undergoing a significant transformation, optimizing operations and delivering a more streamlined and intelligent approach to manufacturing. Let’s delve into the profound impact of AI on the automotive manufacturing process.

1. Predictive Maintenance

One of the key benefits of AI in automotive manufacturing is predictive maintenance. AI-powered algorithms analyze data from sensors and machinery to predict potential equipment failures before they occur. By identifying issues in advance, manufacturers can schedule maintenance proactively, minimize downtime, and optimize productivity on the production floor. This predictive approach helps reduce costs and enhances overall operational efficiency.

2. Quality Control and Inspection

AI systems are being utilized in automotive manufacturing for quality control and inspection processes. Machine learning algorithms can analyze visual data from cameras and sensors to detect defects, inconsistencies, or deviations in manufacturing components and finished products. This real-time feedback enables manufacturers to address quality issues promptly, maintain standards, and ensure the delivery of high-quality vehicles to customers.

3. Supply Chain Optimization

AI technologies play a pivotal role in optimizing the automotive supply chain. By analyzing vast amounts of data related to inventory levels, demand forecasts, supplier performance, and logistics operations, AI systems can streamline supply chain management processes. Automakers can leverage AI-driven insights to make informed decisions, reduce lead times, minimize inventory costs, and enhance overall supply chain efficiency.

4. Robotics and Automation

AI-powered robotics and automation solutions are transforming the automotive manufacturing landscape by enabling greater precision, speed, and flexibility on the production line. Collaborative robots, or “cobots,” work alongside human workers to perform repetitive tasks with high accuracy and consistency. AI algorithms optimize the coordination of robots, increasing efficiency in assembly, welding, painting, and other manufacturing processes.

5. Process Optimization and Simulation

AI algorithms are utilized to optimize complex manufacturing processes and simulate various scenarios to improve workflow efficiency. By analyzing historical data, AI can identify bottlenecks, redundancies, or areas for improvement in the manufacturing process. Manufacturers can conduct simulations and predictive modeling to test different scenarios, anticipate outcomes, and implement changes that enhance productivity and reduce costs.

6. Personalized Production

AI enables automotive manufacturers to cater to personalized production demands by offering customizable features and configurations for vehicles. Through data analysis and predictive modeling, automakers can anticipate customer preferences, market trends, and individual requirements to tailor production processes accordingly. This personalized approach enhances customer satisfaction and competitiveness in the automotive market.

The integration of AI into the automotive manufacturing process is reshaping the industry landscape, driving efficiency, innovation, and competitiveness. By leveraging AI technologies for predictive maintenance, quality control, supply chain optimization, robotics, process simulation, and personalized production, automakers are embracing a future of intelligent manufacturing that is agile, efficient, and customer-centric. As AI continues to advance, the automotive industry is poised to achieve new heights of innovation and excellence in manufacturing processes.