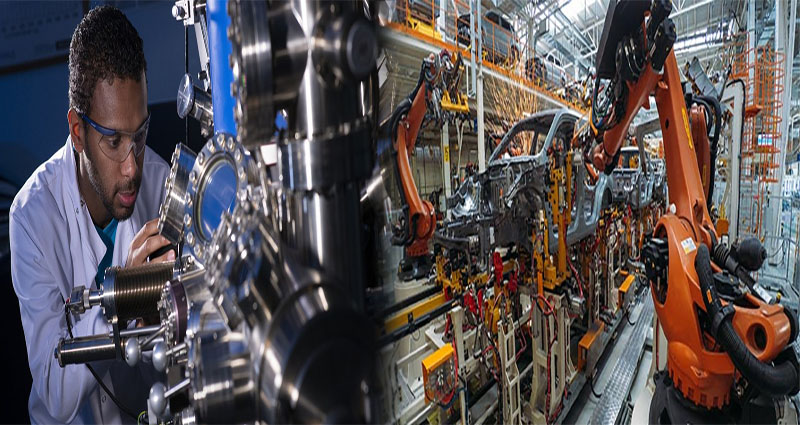

In the realm of modern automobile engineering, the use of advanced materials has revolutionized the way vehicles are designed, manufactured, and perform on the road. From carbon fiber to high-strength steel, these cutting-edge materials offer enhanced strength, durability, and efficiency, leading to safer, more fuel-efficient, and environmentally friendly vehicles.

1. Carbon Fiber

Carbon fiber has become synonymous with high-performance automobiles due to its exceptional strength-to-weight ratio. This lightweight material is significantly lighter than traditional steel or aluminum, making it ideal for enhancing a vehicle’s agility and speed. Carbon fiber is commonly used in body panels, chassis components, and interior trim, contributing to both improved performance and fuel efficiency.

2. Aluminum Alloys

Aluminum alloys are another advanced material widely utilized in modern automobile engineering. Known for its lightweight properties and corrosion resistance, aluminum is often used in the construction of vehicle bodies, engine components, and structural elements. The use of aluminum alloys helps reduce the overall weight of the vehicle, enhancing fuel efficiency while maintaining structural integrity and crash safety standards.

3. High-Strength Steel

High-strength steel alloys have long been a staple in automobile manufacturing, offering superior strength and durability compared to conventional steel. By incorporating high-strength steel in critical structural components like the vehicle frame and safety cage, automakers can enhance crashworthiness and occupant protection. This advanced material plays a crucial role in improving overall vehicle safety while maintaining a balance between weight savings and structural integrity.

4. Composite Materials

Composite materials, such as fiberglass and carbon fiber reinforced polymers, are gaining popularity in modern automobile engineering for their versatility and strength. These materials are used in a variety of applications, including body panels, suspension components, and interior trims. Composites offer advantages in terms of weight reduction, corrosion resistance, and design flexibility, allowing automakers to create innovative and aerodynamic vehicle designs.

5. Thermoplastics

Thermoplastics are increasingly being incorporated into modern automobile design for their lightweight properties, impact resistance, and recyclability. These advanced materials are used in various components, including bumpers, interior panels, and under-the-hood applications. Thermoplastics offer benefits such as reduced weight, improved fuel efficiency, and enhanced sustainability through recyclability, making them a preferred choice for eco-conscious automakers.

The integration of advanced materials in modern automobile engineering has transformed the way vehicles are designed, manufactured, and operated. From carbon fiber to high-strength steel, these materials offer a host of benefits, including improved performance, fuel efficiency, safety, and sustainability. As automakers continue to push the boundaries of innovation, the use of advanced materials will play a pivotal role in shaping the future of the automotive industry, leading to vehicles that are not only cutting-edge but also environmentally friendly and economically sustainable.